Intel - Ho Chi Minh City

Intel - Ho Chi Minh CityDescription

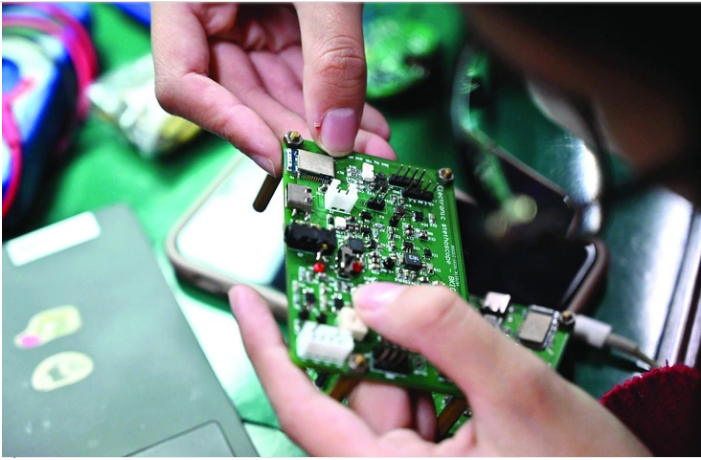

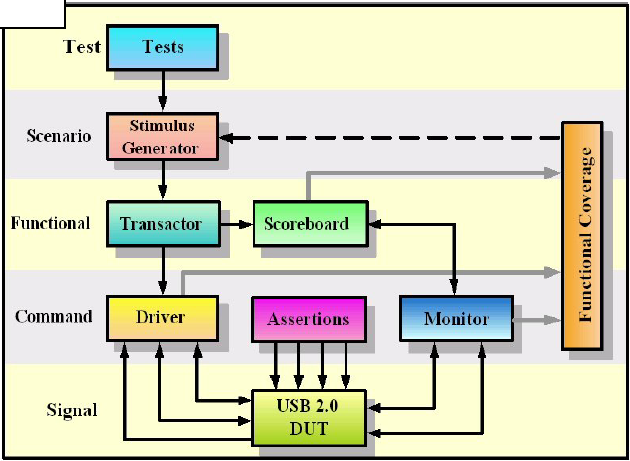

Job Description: Develops new or modified process formulations, defines processing or handling equipment requirements and specifications, and reviews processing techniques and methods applied in the manufacture, fabrication and evaluation of semiconductors. Reviews product requirements with design staff to ensure compatibility of processing methods. Compiles and evaluates test data to determine appropriate limits and variables for process or material specifications. May conceive and plan projects involving definition and selection of new concepts and approaches in the processing or development of new or improved processes in photomasking, diffusion, deposition, wafer fabrication and device physics. Works on complex issues where analysis of situations or data requires an in-depth evaluation of variable factors. Exercises judgment in selecting methods, techniques and evaluation criteria for obtaining results. Qualifications

Must possess a Bachelor or a Master of Science degree in Electrical, Mechanical, Mechatronics and/or other related majors. Additional qualifications include: - Ability to work on 12 hours shift, day or night

- Strong verbal and written communication skills in English

- Familiarity with statistical data analysis techniques

- Demonstrated excellent problem solving skills

- Ability to travel and/or relocate to another city or country for training

- Familiarity with semiconductor packaging and testing technologies, process and equipment would be an added advantage

Job Category

: EngineeringPrimary Location

: Viet Nam-Vietnam, Ho Chi Minh CityFull/Part Time

: Full TimeJob Type

: College GraduateRegular/Temporary

: RegularPosting Date

: May 21, 2015Apply Before

: OngoingBusiness Group As the world's largest chip manufacturer, Intel strives to make every facet of semiconductor manufacturing state-of-the-art -- from semiconductor process development and manufacturing, through yield improvement to final test and optimization, and lastly packaging. Employees in the Technology and Manufacturing group are part of a worldwide network of manufacturing and assembly/test facilities. The Assembly and Finish Engineer is responsible for: - Installing, qualifying and put into operation the Assembly and Finish equipment and process. - Implementing the process control systems and monitoring the process to detect signals and maintain it within control, so no safety or quality incident occur and performance targets are met. Monitor equipment and process indicators to reduce process variability. - Defining maintenance procedures, training manufacturing technicians and partnering with Manufacturing to maintain the equipment with the highest standards. Will use High Precision Maintenance methods to execute and improve preventive maintenance of the equipment. Provide basic and advance troubleshooting to manufacturing equipment including corrective and preventive maintenance. - Coordinating, implementing and developing equipment and process improvements in regards to safety, quality and efficiency. Will use lean rules, principle and methods to determine improvement opportunities and develop solutions. Will resolve process problems by applying structured problem methodologies (Model Based Problem Solving, Lean and Statistics). - Module critical success indicators and collaborating with other engineering functions in Mfg. process and systems improvements. Owns processing or handling equipment specification.

Posting Statement: N/A